On Saturday we already explained why floor insulations should always be dried by a certified company. Furthermore, we explained that here an under pressure drying is made and how that method works. Today we want to explain you the details of that method and show you solutions of typical problems which can occur during the drying process.

To dry floor insulations the air in the insulating layer must circulate. Typically, air influxes through the opened border joints and is sucked up through drilled holes in the screed again. Of course, you destroy the flooring with the drillings. When you have a ceramic tilling there is no problem if you have some tiles in reserve. When the flood has already destroyed the flooring you don’t have to think about it as well.

But what to do when the flooring still is intact and I don’t want to damage it while drying?

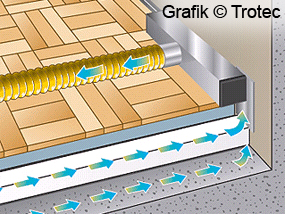

For parquet and laminate experts often choose the slot nozzle method. Special slot nozzles suck up the process air out of the insulating layer. On the opposite side of the room the air influxes the layer again through the opened border joints and flows through the whole floor insulation. When using this method you only have to dismantle the skirting boards. The flooring itself remains as it is.

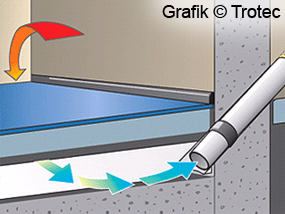

Alternatively, you can choose the diagonal drilling method. Using this technique you don’t drill holes into the flooring but from one or more neighbour rooms diagonal through the wall. Here the flooring remains intact as well and you even can use the room while the drying is in process.

Alternatively, you can choose the diagonal drilling method. Using this technique you don’t drill holes into the flooring but from one or more neighbour rooms diagonal through the wall. Here the flooring remains intact as well and you even can use the room while the drying is in process.

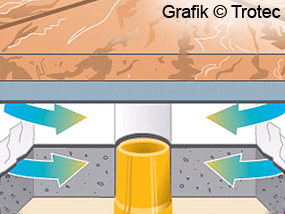

Another possibility  to not damage the flooring is the underfloor technology. Here the drillings are through the concrete ceiling into the insulating layer made from the floor below. The room air (dried by condensation dryers) influxes the layer through the opened border joints, flows through the wet insulating layer and then is sucked up through side channel compressors. This method is not only used when you don’t want to damage the flooring but also when, for example, shops or business premises should not be affected by the drying.

to not damage the flooring is the underfloor technology. Here the drillings are through the concrete ceiling into the insulating layer made from the floor below. The room air (dried by condensation dryers) influxes the layer through the opened border joints, flows through the wet insulating layer and then is sucked up through side channel compressors. This method is not only used when you don’t want to damage the flooring but also when, for example, shops or business premises should not be affected by the drying.

What to do when I don’t have any  tiles in reserve?

tiles in reserve?

When drying in tiled areas the tiles don’t necessarily have to be drilled through. Using a special tile lifting system it is possible to remove single tiles from the ground without damaging them. Afterwards the drillings are made and the drying can start. After the drying you just put the removed tiles back in place. With that method you can avoid an expensive retiling or an unsightly reparation with similar tiles.

The certified company in your area can check which of the explained methods is the best for you.

Do I have to keep an eye on anything special? What about my furniture and my plants?

Most condensation dryers have a water tank to collect the water. Of course, you have to empty the tank regularly.

You can leave your furniture in the room during the drying process. You can wrap a protection foil round your solid wood furniture if necessary. Very sensitive things like antiques, musical instruments art objects and plants should be removed out of the room.

Depending on the outdoor climate it can get very warm while drying. If the room temperature through the waste heat of the drying units climbs over 25 °C shut them down for a few minutes and ventilate the room.

Trotec Flood Info: To inform you in any case of damage

We inform you about the following topics in detail:

- Trotec assists flood victims with expertise

- How long does a dehumidification take?

- Should I rent or buy a drying unit?

- Trotec Flood Info: The right moisture measurement after flood damages

- Trotec Flood Info: When do I need an expert?

- Trotec Flood Info: What to do when mould attacks?

- Trotec Flood Info: How to dry floor insulations

- Trotec Flood Info: What to do against the smell after the flood damage?

- Trotec Flood Info: The main facts about drying units