The third part of our guide series is about chimney oil fan heaters, also called indirect oil heaters. Whether in building shells, in the warehouse, workshop or in agriculture – thanks to this heating system, no professional has to freeze at work even in indoor spaces with limited ventilation. Because the big advantage of chimney heaters is that their warm air contains neither water vapour nor combustion exhaust gases. With their both dry and exhaust-free heat, they are therefore perfectly suited for indoor use.

So if you want to generate clean and at the same time dry heat, we recommend using indirect oil heaters. Because unlike direct oil heaters, no exhaust fumes or water vapour enter the room air. Instead, both are directed outside through the chimney. We explain how this heater exactly works, where it can be used best and what needs to be taken into account when it comes to its thermal efficiency.

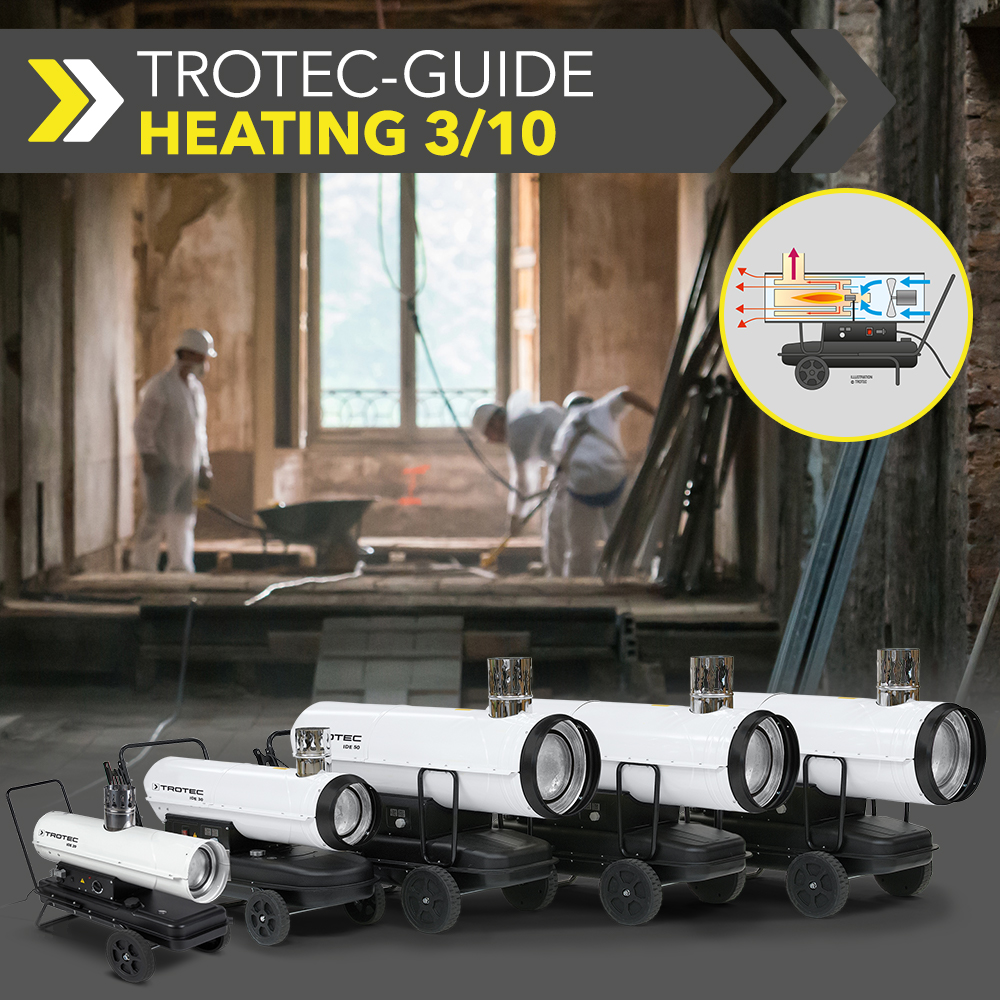

Chimney oil heaters – how they work

Indirect heaters with a chimney completely separate the air to be heated from the combustion chamber. The air is heated by directing it past the enlarged area of the combustion chamber, the heat exchanger. Although the fan, which blows the warm air into the room to be heated, also provides the required combustion air, the combustion products are nevertheless discharged outside through a chimney – the significant feature of the ‘indirect’ ones.

How chimney oil heaters are ideally used

Indirect heaters are ideal for rooms where limited ventilation is possible, but where they should still be used by both people and animals alike. They are also a good choice for accelerating the drying of buildings and in rooms where there is a fire hazard due to the presence of flammable substances.

Chimney oil heaters have a somewhat lower thermal efficiency

The efficiency of indirect oil heating devices with chimney is slightly lower than that of direct oil heating devices without chimney. Since indirect chimney oil heaters, depending on the model, discharge approx. 5 to 8 % of the heating energy together with the exhaust gases and water vapour through the chimney to the outside, their efficiency compared to direct oil heaters without chimney is only approx. 92 to 95 % instead of 100 %.

Good to know: Chimney oil heaters …

- completely separate the heated air from the combustion chamber

- have a chimney as a significant feature

- in contrast to directly fired oil and gas heaters, discharge the combustion exhaust gases through the chimney and do not release these into the room

- achieve a thermal efficiency of approx. 92 to 95 %, since approx. 5 to 8 % of the heat output is lost through the chimney

- produce clean (soot-free) and dry (condensate-free) heat

- can be used in unventilated rooms with people and animals inside

- are suitable for accelerating the drying of buildings

Trotec brand quality – indirect chimney oil heater fans in all performance classes from 20 KW to 375 kW

- Click here to go to an overview of the professional heaters from Trotec

- Or you can call our team of experts for a purchase at +49 2452 962-400 or for rent at +49 2452 962-160 or use our contact form. We provide advice when it comes to choosing one and answer your questions regarding all heating related topics.

Overview of the Trotec guide ‘Heating’

1/10 Direct oil heaters – can be used in well-ventilated indoor spaces and covered outdoor areas

2/10 Direct infrared oil heaters – precisely directed infrared heat radiation

3/10 Chimney oil heaters (indirect oil heaters) – exhaust-free heat for indoor use

4/10 Gas fan heaters – affordable heat for well-ventilated indoor spaces

5/10 Electrical hot air fans – convenient, safe, clean and fast heat

6/10 Infrared radiant heaters – heat right where it is needed with no warm-up time

7/10 Quick comparison – which heating type for which intended purpose?

8/10 HEATBOX – energy savings of up to 70 % when heating tents and halls

9/10 Accessories for heaters outside the home – solutions from Trotec

10/10 Calculating the required heat output – the online heat output calculator from Trotec