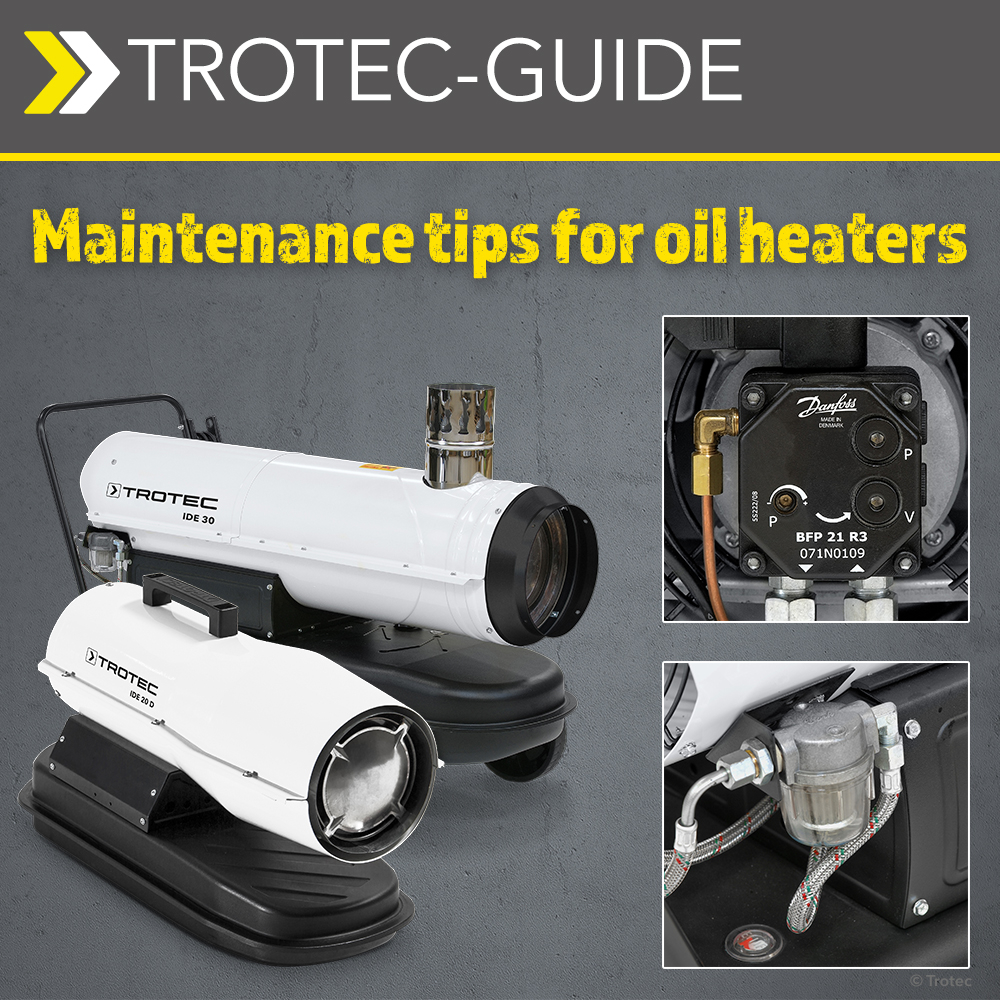

Increasingly colder temperatures also affect hard-boiled workers in building shells, warehouses or cattle sheds. Now is the time to start the mobile oil heaters up again. But if it was simply put away after its last use, you should clean the oil heater and ensure it works properly before turning it on again – before it starts to ‘spit’, in other words the flame burns irregularly, or worse. The Trotec guide tells you what you should pay attention to in general – not only in terms of the oil heater fans in our IDE series …

Increasingly colder temperatures also affect hard-boiled workers in building shells, warehouses or cattle sheds. Now is the time to start the mobile oil heaters up again. But if it was simply put away after its last use, you should clean the oil heater and ensure it works properly before turning it on again – before it starts to ‘spit’, in other words the flame burns irregularly, or worse. The Trotec guide tells you what you should pay attention to in general – not only in terms of the oil heater fans in our IDE series …

As a reminder: direct oil heaters are ideal for use outdoors or in well-ventilated indoor spaces because they provide all the generated heat; in other words, you benefit from 100% heat output. However, because a lot of moisture is released during combustion, direct heaters should never be used to dry buildings. The indirectly fired fan heaters can also be used to heat closed rooms when using the optionally available flue gas exhaust. So, let’s dive right in:

What you should do before carrying out the maintenance of the unit

Please pay attention to the electrical voltage: do not touch the mains plug with damp or wet hands and turn off the unit. To do this, unplug the mains cable from the mains socket by gripping it at the plug. If you have already put the unit into operation, let it cool down completely.

Warning of electrical voltage

Activities that require opening the housing may only be carried out by authorised specialist companies or Trotec!

How to clean the housing

Clean the housing with a moistened, soft, lintfree cloth. Ensure that no moisture penetrates into the housing. Ensure that no moisture can come into contact with electrical components. Do not use any aggressive cleaning agents, such as cleaning sprays, solvents, agents containing alcohol or scouring agents to moisten the cloth. Wipe the housing dry after cleaning it.

How to ensure the unit works properly

The combustion chamber, burner and fan should be cleaned before recommissioning. In addition, regular cleaning is recommended every 50 operating hours. It is best to follow these instructions and then assemble the components in reverse order:

- Dismantle the heating oil filter. Remove the filter element and clean it with clean heating oil.

- Dismantle the top section of the housing and clean the inside as well as the blades of the fan with a cleaning fleece and with a brass brush if heavily soiled.

- Check the condition of all cables and high voltage connectors.

- Dismantle the burner and clean its components with a brass brush.

- The nozzle should also be cleaned with the brass brush.

- Check the ignition electrode for contamination and replace it if necessary.

- Check the distance between the electrodes and adjust if necessary.

- Check if the fuel line is porous or leaking and draws air, or if the sight glass is cracked or has hairline cracks. This also results in so called ‘air leakage’.

- Have customer service clean the combustion chamber.

More information on direct oil heaters from Trotec

An all-in-one price and heating cannon – that’s how Trotec’s IDE oil heater fans are aptly described. With heating outputs between 20 kW and 100 kW, they are regarded as both economical and reliable solutions for typical mobile heating applications at construction sites, in halls and workshops as well as in agriculture. More information is available online – in our Trotec-Shop!