-

Infectious aerosols in room air represent a risk factor so far overlooked

Infectious aerosols in room air represent a risk factor so far overlooked -

High-performance air purifiers with H14 high-performance filters from Trotec can be used immediately to provide maximum protection against infection

-

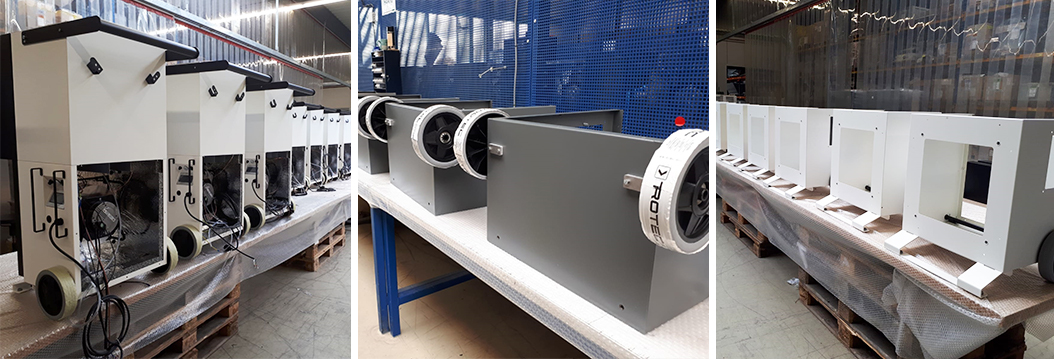

The technology developed in Heinsberg is available immediately and can be adapted as a solution for the entire industry

How more than 1500 employees of the Tönnies slaughterhouse in Gütersloh were able to become infected with the coronavirus within a very short time and what technical solutions from Heinsberg are to minimise the risk of infection in the meat industry in future is currently being investigated by a working group comprising employees of the State Centre for Health as well as the Robert Koch Institute. This investigation is led by Professor of Hygiene Martin Exner, Director of the Institute for Hygiene and Public Health at the University of Bonn. The initial insights and approaches were presented at a press conference on 24 June 2020 in the Gütersloh Municipal Centre.

Previously overlooked risk factor in the meat industry: infectious aerosols

What aerosols experts such as Dr Thomas Voshaar, Advisor to the Federal Health Minister Jens Spahn, and the Heinsberg room air experts at Trotec, a leading company throughout Europe in the manufacture of industrial filter systems with high-performance technology, have long been warning has now been substantiated by the investigation into the corona outbreak at the Gütersloh meat plant Tönnies. Besides droplet and smear infection, the coronavirus primarily spreads via room air.

More precisely through so-called aerosols, a mixture comprising gas (usually air) and solid or liquid constituents, which contain viruses in infected persons. These tiny suspended particles are released into the room during breathing and talking. While larger droplets fall to the floor after approx. 1.5 metres owing to their weight (hence the social distancing rule of 1.5 m), infectious aerosol particles sometimes remain suspended due to their small size (approx. 0.3-0.4 µm) for several hours in the room air inside the meat cutting area cooled to 6 – 10°C, where they are permanently circulated around the room by the ventilation system – and continuously breathed in! An infection risk that has not yet been discussed adequately in scientific depth, according to Martin Exner.

Innovative TAC V+ air purification technology with high-performance filters should provide help

“What is not known so far: Circulating air can keep an aerosol in motion – this represents a previously overlooked risk factor.” Conventional air-conditioning systems have only a coarse filtration, which is not able to filter out airborne viruses, according to Prof. Exner in an analysis of the infection transmission at Tönnies. Help should now be provided by the innovative TAC V+ air purification technology from Trotec, whose mobile and decentralised high-performance filtration ensures that the germ-laden room air of the slaughterhouse meat cutting area is kept free of airborne microorganisms like the SARS CoV-2 virus. The heat-resistant HEPA high-performance filter of filter class 14 developed by Trotec is also treated thermally so that viruses are not only separated from the air but also inactivated in the device.

This air purification principle is not entirely new. It is typically used in hospitals in order to keep the air free of germs and viruses in operating theatres. However, a mobile solution with a comparably high protection level has not been available so far for industry. “This is really important to me” – a high-performance filtration, as can potentially be enabled by the TAC V+ air purifier in areas of the meat industry, was not previously envisaged in any statutory regulation. Therefore, according to Prof. Exner, the pattern of infection in the slaughterhouses does not involve failures in prevention either, as there is still a lot to be learnt about the new pathogen.

Insights from Heinsberg are helping to analyse the infection transmission

The visit to the Tönnies plant conducted at the weekend was also accompanied by insights from the infection transmission in Heinsberg – from where the virus spread across the entire country after a carnival event in February. At this event too, aerosols in the room air were suspected to be the main transmission route of the virus. The pathogen was spread via the air circulation of the air-conditioning system, which did not have any special virus filter.

Until now, the measures in the meat cutting areas of the food industry focussed solely on assuring the meat quality. For this purpose, the room temperature in these production areas is lowered and also dehumidified, in order to keep the growth of microorganisms such as listeria and salmonella under control. The high-performance TAC V+ air purifiers developed in Heinsberg are also intended to curb the risk of infection with the SARS-CoV-2 pathogen in future.

High-performance filtration can be adapted to all areas of the industry

The task of the working group now convened will be to identify the areas in meat production where the aerosol movement in the recirculation of the room air plays a role. If these production processes are kept free of germs and viruses by the use of corresponding TAC V+ high-performance air purifiers, the infection risk will drop to almost zero in this part of the meat production.

The mobile TAC V+ air purifier is available in several colours and equipment variants.

Feel free to talk to us personally:

Trotec GmbH, Mr Jochem Weingartz

Telephone: +49 2452 962-137, jochem.weingartz@trotec.com

How the active principle behind high-performance filtration works

A critical factor in the risk of infection with the coronavirus is how long the virus-laden aerosols remain in the room air. This is because – in contrast to the open air, where aerosol mixtures are diluted and replaced with fresh air by the air motion – the aerosol concentration remains continually high in class rooms. The more aerosols are suspended in the air – and the longer they remain so – the faster these enter the body via the respiratory tract to cause an infection in the lungs. Even if children have a low risk of infection – as assumed by individual virologists – the risk for the teaching staff remains as high as before. Around 50,000 particles, such as dust or pollen but also bacteria and viruses, are suspended in just one cubic centimetre of air. And with each further pupil in the class, the aerosol concentration in the room increases by thousands of particles per minute.

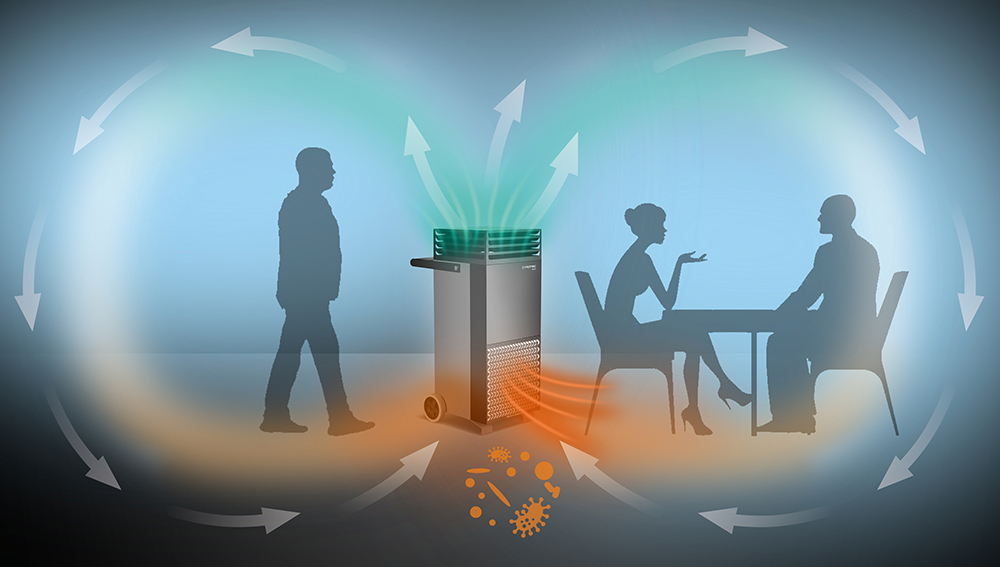

Put simply, the TAC V+ air purifier transforms the air situation outdoors to the situation in closed rooms and extends this by a highly efficient virus filtration and inactivation.

The air filtration concept behind the TAC V+ air purifier tested in clinical trials is based on two pillars:

- On the one hand, the aerosol concentration in the room air is continuously diluted with virus-filtered HEPA ultrapure air. To this end, the purifier has a high ultrapure air capacity – previously unattained with mobile devices – which enables an air exchange rate up to 20 times per hour.

- In addition, airborne viruses and bacteria are first separated in an innovative, heat-resistant HEPA particulate filter and then killed off cyclically by thermal decontamination. This special filter of protection class 14 exclusively developed by Trotec is distinguished by a separation efficiency of 99.995 percent for particle sizes from 0.1 to 0.2 µm. Thanks to these features, H14 high-performance filters are even used to produce clean air in operating theatres and in similar hygiene-sensitive areas.

What sounds very technical in theory proves to be really simple in practice. The draught-free intake of polluted room air occurs close to the floor, the ultrapure air free of viruses then being returned vertically upwards into the room. Thanks to the mobile design enabling several TAC V+ air purifiers to be used, even large areas of ultrapure air without hazardous aerosol contamination can be realised.